About Us

CAPACITY AND PRODUCTION

Welltan Fashions boasts an impressive installed capacity of approximately 700,000 square feet per month. In a remarkably short period, the tannery has rapidly scaled its production capabilities, consistently delivering substantial volumes of high-quality leather each month.

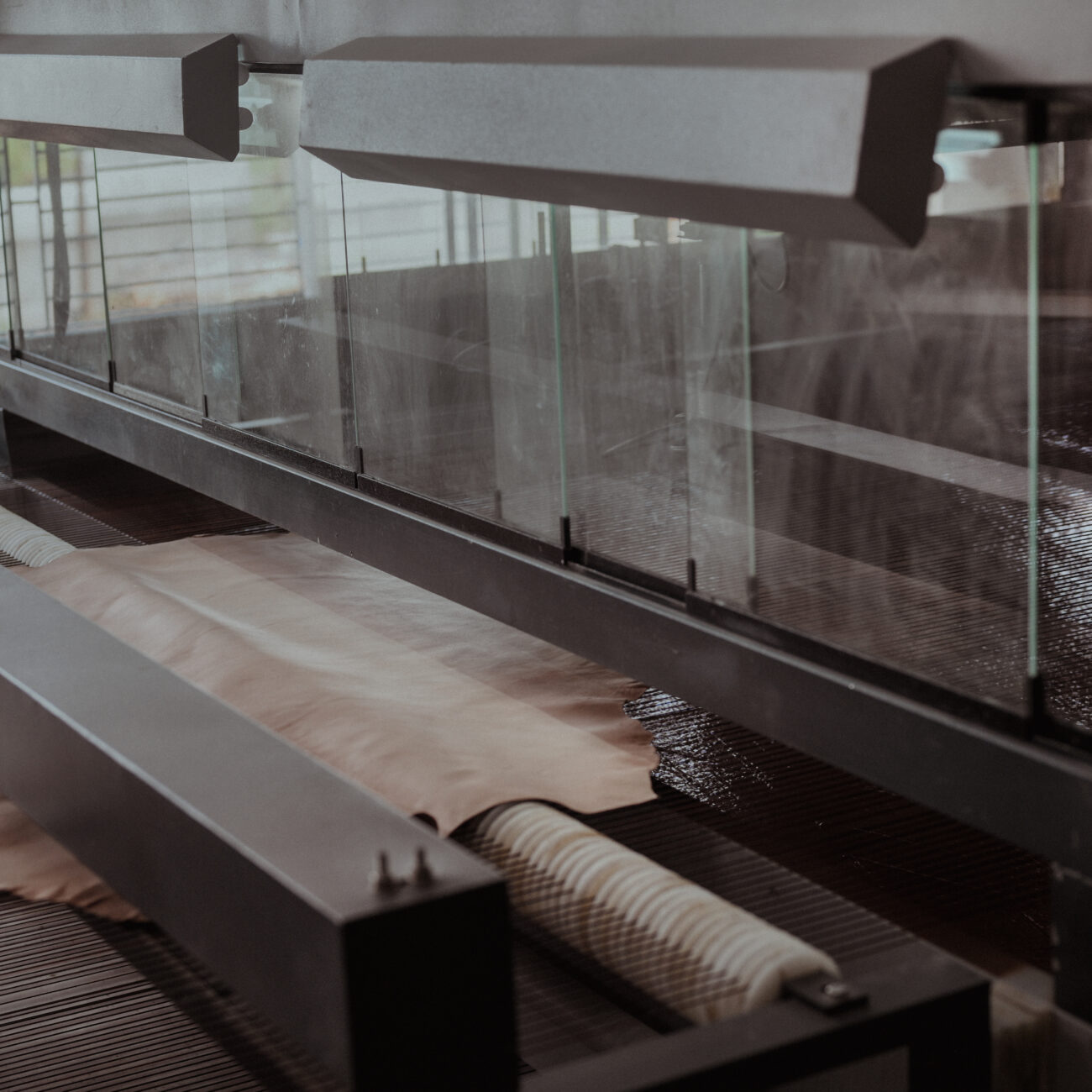

PLANT AND MACHINERIES

All major machinery at Welltan Fashions is imported from renowned Italian manufacturers specializing in tannery equipment, including esteemed brands such as

RAW MATERIAL

AND PRODUCTS

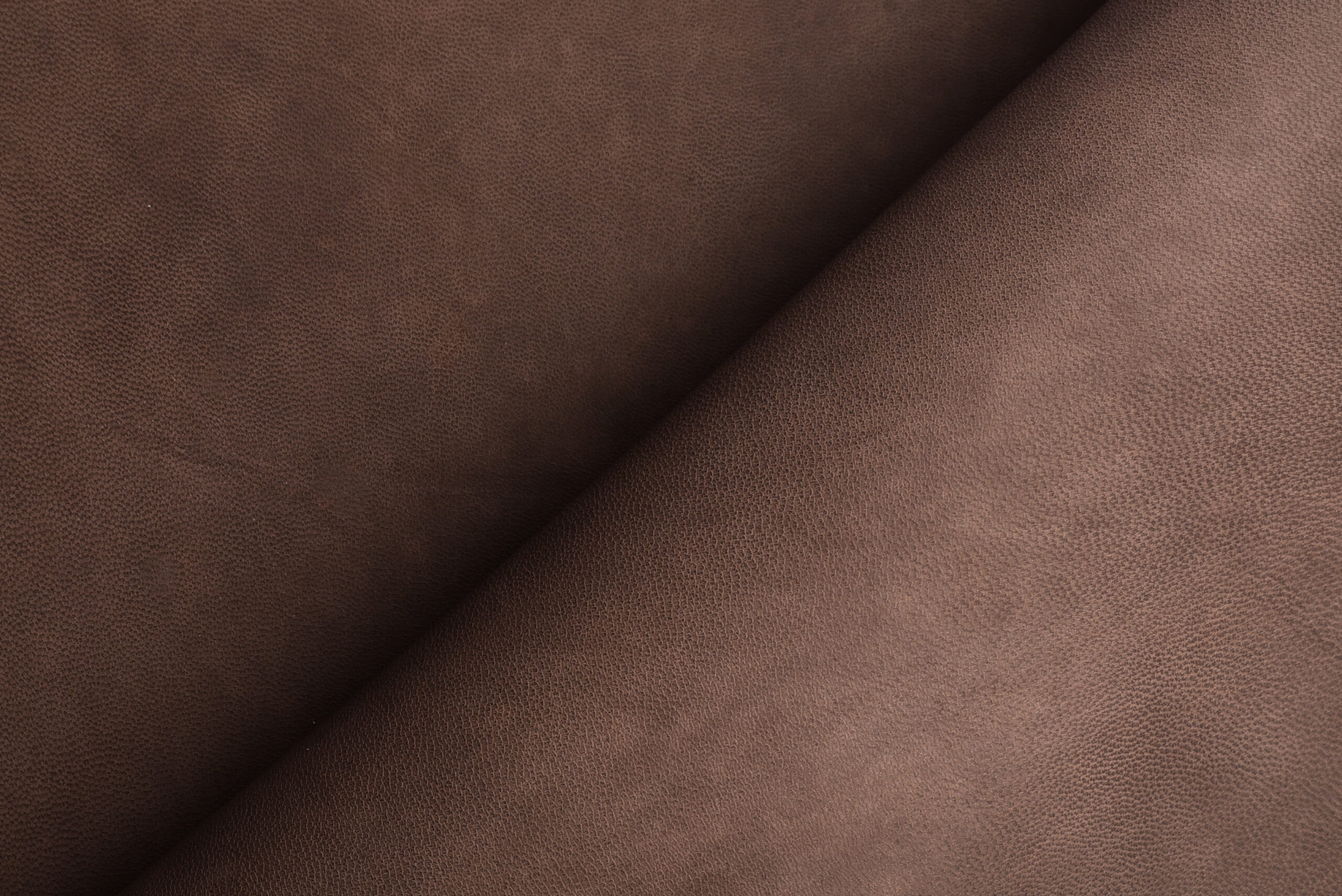

At Welltan Fashions, we specialize in the production of Cow, Goat, and Sheep leathers, available in Naked, Finished, and Crust forms. Our leathers are crafted from both Indian and imported raw materials, with Cow Hides sourced from premium suppliers in New Zealand, Brazil, Poland, Italy, and Germany.

Our exclusive product range is designed to add significant value to Leather Goods, Belts, and Footwear. We offer a variety of finishes, including

In addition, we produce the following specialized leathers in substantial quantities

OUR GALLERY

Explore the heart of our production process through visuals that highlight the precision, tradition, and technology behind our premium leather.

QUALITY CONTROL

Wet Blue Selection

Crust Selection

Finished Goods Selection

This meticulous multi-layered quality control system ensures that every product we deliver meets the highest standards of performance and aesthetic quality.

This meticulous multi-layered quality control system ensures that every product we deliver meets the highest standards of performance and aesthetic quality.